Washing Machine

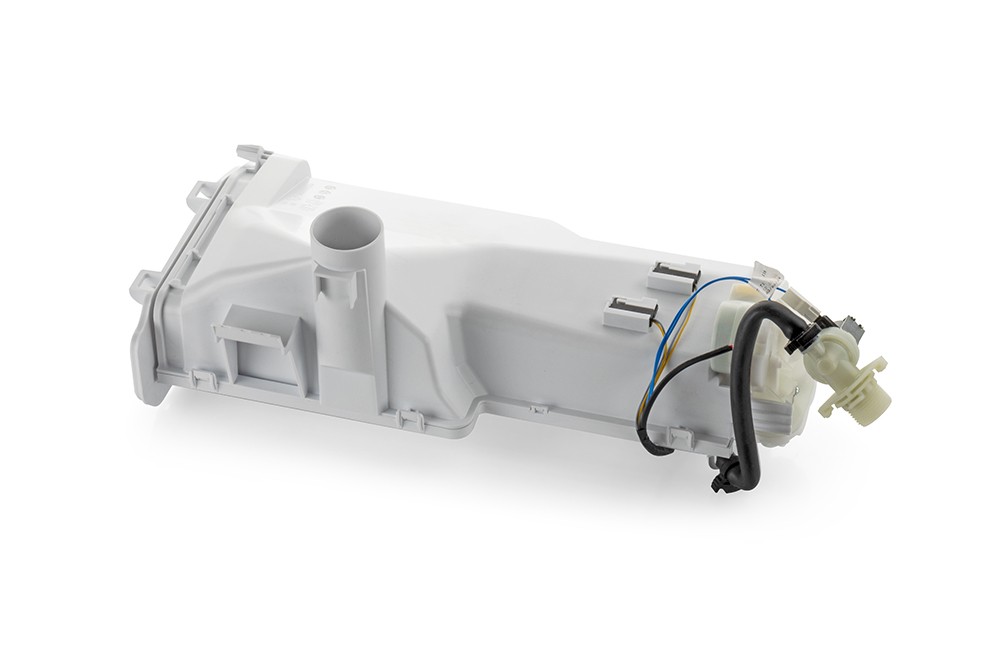

Plastic components used in washing machines are produced. Injection technology is used on the bearing housing in the production of heavy-weight parts such as the washing machine drum, which is one of the most important parts that requires technology and experience. We also have all the necessary capabilities for products that require the use of more than one technology and raw material for aesthetic reasons, such as control panels. Our company successfully carries out its production processes using Lexan materials and advanced technologies and applications such as hot stamping, screen printing, vibration and ultrasonic welding.

-

Control Panels: Control panels, which are the user interface of washing machines, tumble dryers and dishwashers, are manufactured from durable and aesthetic materials.

-

Lexan Materials: Lexan is a material known for its high impact resistance and transparency. The use of Lexan in various visual components of white goods, especially control panels, allows for the production of products that are both aesthetically pleasing and durable.

-

Hot Stamp: We use hot stamping technology to apply aesthetically pleasing and durable press to our products. This method uses appropriate heat and pressure to create permanent, high-quality press on the product surface.

-

Vibration and Ultrasonic Welding: We use vibration and ultrasonic welding technologies to create strong and reliable connections at the joints of parts. These methods ensure strong, leak-proof connections between parts.